ARMORFORM® Fabric-Formed Concrete Revetment Systems

The ARMORFORM® erosion control system utilizes double-layer woven geotextiles engineered exclusively to serve as forms for casting concrete erosion control revetments and linings. The forms are woven from nylon and/or polyester yarns and are designed with the required mechanical and hydraulic properties of a superior textile form.

ARMORFORM® is positioned on the subgrade to be protected, where it is inflated with pumpable fine aggregate concrete (structural grout) to form an erosion control mat. ARMORFORM® mats should be placed over a site-specific filter fabric.

ARMORFORM® is available in various styles and thicknesses. Uniform Section Mat (USM), Filter Point Mat (FPM), Articulating Block Mat (ABM), and Armor Bags are the four standard forms. For the majority of applications, one of the standard styles and thicknesses of ARMORFORM® should prove adequate. However, customized configurations and/or thicknesses can be manufactured to meet specific requirements. In applications where there is a need for revegetation of an eroded embankment, mats can be produced to inflate to over 24 inches thick.

-

- Unlike conventional concrete, ARMORFORM® can be installed underwater.

- Unlike riprap, ARMORFORM® is of consistent size and weight. It will also function as a mat (with a fairly low Mannings “N” value) instead of individual units. This allows the designer to utilize an ARMORFORM® mat of considerably less thickness and weight to equal the performance of riprap.

- Unlike gabions, precast concrete block mats or riprap, ARMORFORM® can be installed without the use of heavy equipment. Since the concrete is pumped into the mat through a hose, the trucks delivering the concrete can also be parked up to several hundred feet away from the actual site. This allows for installations in even the most inaccessible project sites.

- Unlike most other hard armor systems, ARMORFORM® is simply a form for concrete. Concrete is then purchased from a local supplier of choice. By shipping the light-weight forms to the project site (and not the actual armor unit itself), as much as 30% can be saved from the overall cost simply due to much lower freight charges.

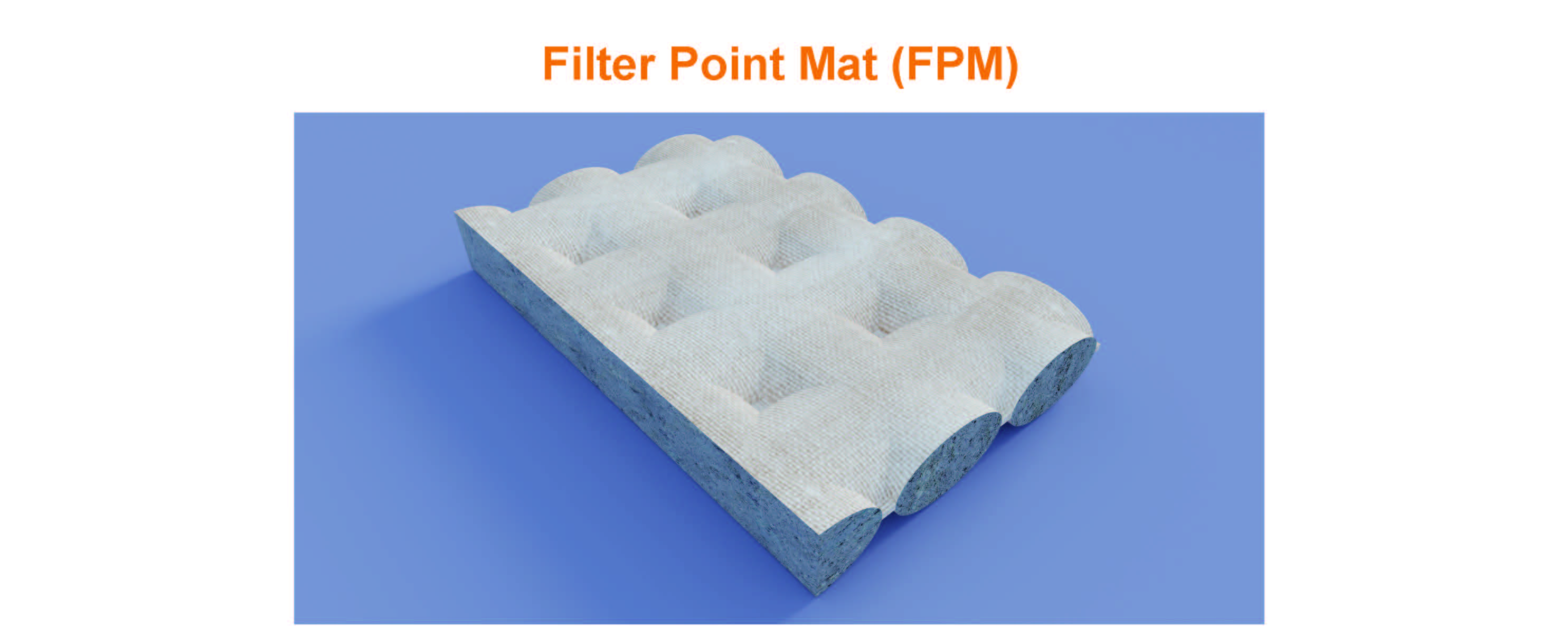

Filter Point Mat (FPM)

Filter Point Mat (FPM) fabric forms are constructed with spaced interwoven filter points to form a lining of required average thickness, deeply cobbled surface, and specified weight to provide strength and erosion protection. The design criterion for selection of lining thickness is the same as that used to determine the thickness of conventional concrete slope paving. Relief of hydrostatic uplift pressure caused by entrapped and ground water, is provided by the woven filter points which are on 5”, 8” or 10” centers. Filter Point Mat (FPM) is custom fabricated into multiple mil-width panels, designed to fit actual site dimensions and topography.

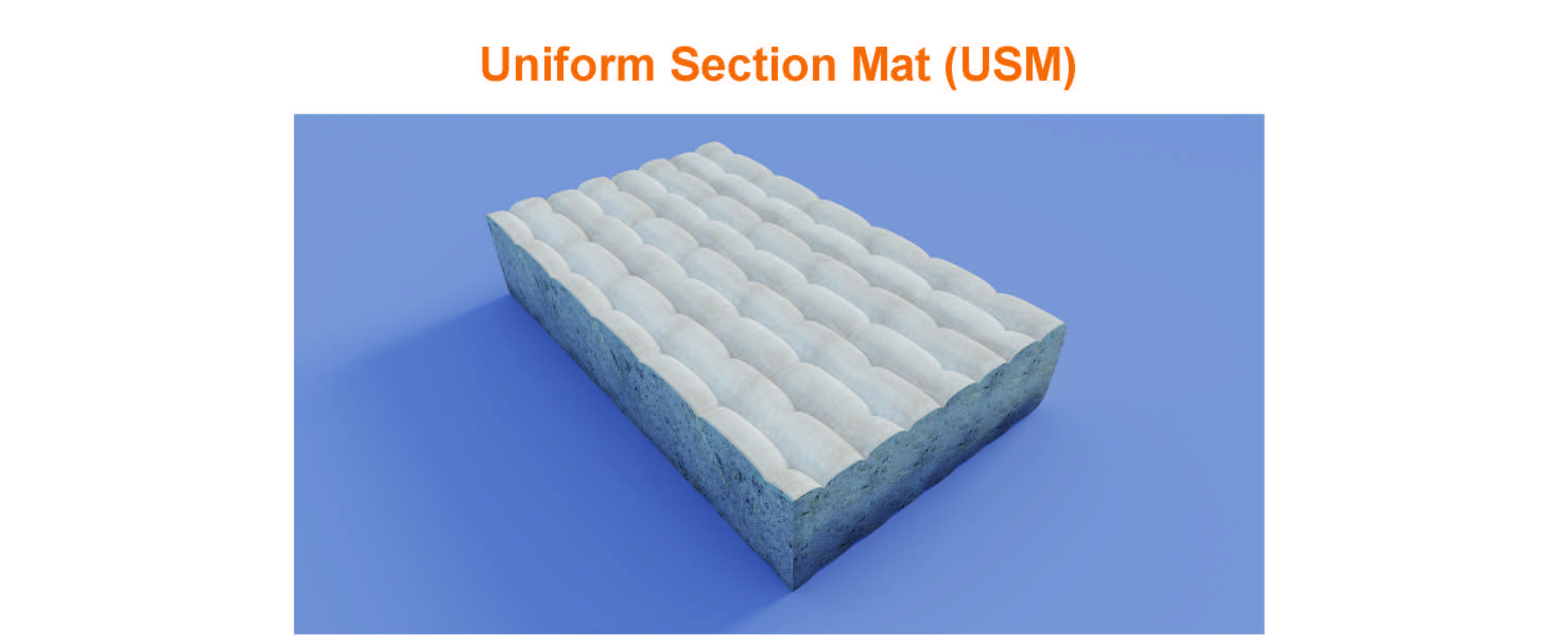

Uniform Section Mat (USM)

Uniform Section Mat (USM) fabric forms are constructed with spacer cords on closely spaced centers to form a lining of required nominal thickness, bonded cobbled surface, and specified weight to provide strength and erosion protection. The design criterion for selection of lining thickness is the same as that used to determine the thickness of conventional concrete slope paving. Relief of hydrostatic uplift pressure caused by entrapped and ground water, may be provided by inserting plastic weep tubes through the mat at specified centers. Uniform Section Mat (USM) is custom fabricated into multiple mil-width panels, designed to fit actual site dimensions and topography.

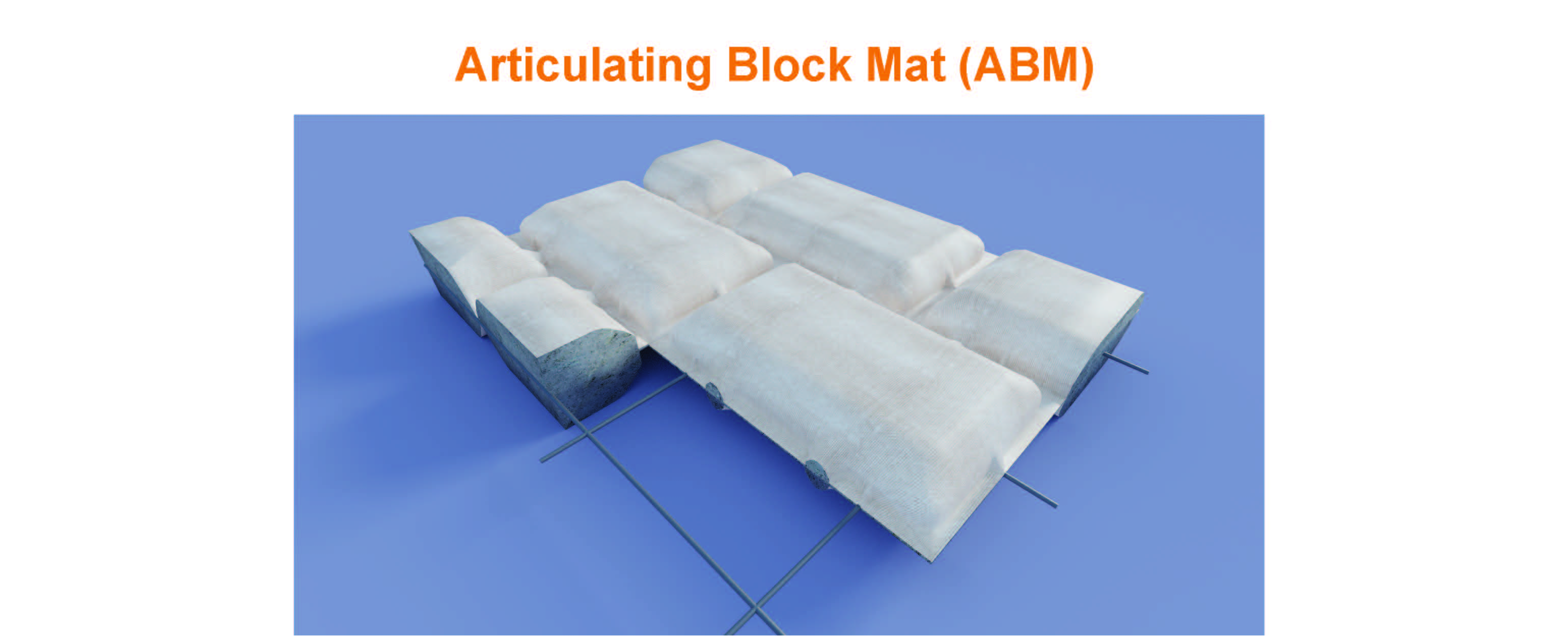

Articulating Block Mat (ABM)

Articulating Block Mat (ABM) is formed with a double layer woven fabric, joined together into a matrix of rectangular compartments. Each compartment is separated by a narrow perimeter of interwoven fabric containing interconnecting, high-strength revetment cables. Articulating Block Mat forms are positioned on the area to be protected, where they are filled with pumpable fine aggregate concrete (structural grout) to form a mattress of individual blocks in a bonded block pattern. The high-strength revetment cables become embedded in the blocks to tie the blocks together and enable the revetment to resist tension in all directions. Patented separate cable duct design assures that the revetment cables will be positioned securely in the center of each block. Relief of hydrostatic uplift pressure caused by entrapped and ground water, is provided through the narrow perimeter of interwoven fabric after the grout has hardened. Articulating Block Mat (ABM) is custom fabricated into multiple mil-width panels, designed to fit actual site dimensions and topography.

Armor Bags

Armor Bags are custom fabricated to fit jobsite requirements. Inlet valves, which are attached by fabric flange to a slit in the surface of the bag, provide positive self-closure. Inlet tubes may be added to extend outside the bag if desired. Durable nylon straps may be attached to the outside of Armor Bags to serve as thickness controllers and to allow filling of tapered or irregularly shaped bags.

- Geotextiles

- TenCate Mirafi Geotextiles N-Series & X-Series

- TenCate Mirafi Geotextiles S-Series

- TenCate Mirafi Geotextiles FW-Series

- TenCate Mirafi Geotextiles HP-Series & PET-Series

- TenCate Mirafi Geotextiles RSi-Series & H2Ri-Series

- TenCate Mirafi Geosynthetics MPV, MPG (PGM-G), and MPG4 (PGM-G4) Paving Fabrics

- Sediment Control & Construction Site BMPs

- Silt Fence

- Straw Wattles

- Floating & Staked Turbidity Barriers

- Applied Polymer Systems Polyacrylamides (PAM)

- Applied Polymer Systems Floc Logs

- Link Manifold System

- Floc Pit System

- Hach Portable Turbidimeter

- Dewatering Bags

- Curb Inlet Protection

- Drop Inlet Protection

- Sand, Sand-Cement & Rock Bags

- Rattle Grate Trackout Control

- FODS Trackout Control Mat

- Outpak Universal Portable Washout

- Erosion Control

- Hydroseeding Mulches

- North American Green Biodegradable Blankets

- North American Green Temporary Erosion Control Blankets

- North American Green Permanent Turf Reinforcement Mattings

- InstaTurf High Performance Erosion Control Mats

- Presto Geosystems Perforated GEOWEB

- Flexamat Concrete Mat Systems

- ARMORFORM Fabric-Formed Concrete Revetment Systems

- IECS Cable Concrete

- Maccaferri Reno Mattresses

- Tencate Geotubes for Shoreline Protection

- Geotextile Tubes for Lake Embankment

- Silt Fence

- Bioengineering Solutions

- Subgrade Stabilization & Load Support

- TenCate Mirafi Geotextiles RSi-Series & H2Ri-Series

- Tensar Biaxial (BX) Geogrids

- Tensar TriAx (TX) Geogrids

- Tensar InterAx (NX) Geogrids

- TenCate Mirafi Geosynthetics MPV, MPG (PGM-G), and MPG4 (PGM-G4) Paving Fabrics

- Presto Geosystems GEOWEB for Load Support

- Presto GEOPAVE

- Presto Geosystems GEOBLOCK & GEOBLOCK5150

- Presto GEOTERRA

- Presto GEORUNNER

- Soil Retention Drivable Grass

- EcoBlock (EB) Recycled Plastic Turf Block

- FODS Trackout Control System

- AGES Mud Mats

- Mud Control Grids

- Slope Reinforcement & Retaining Walls

- Drainage & Stormwater

Resources

-

ARMORFORM Product Brochure

-

ARMORFORM Installation Guide

-

Filter Point Mat Specification Sheet

-

Filter Point Mat Technical Data Sheet

-

Uniform Section Mat Specification Sheet

-

Uniform Section Mat Technical Data Sheet

-

Articulating Block Mat Specification Sheet

-

Articulating Block Mat Technical Data Sheet

-

Armor Bags Specification Sheet